Follow the link below to view in better quality.

Purpose

The purpose of this design project was to make use of Dynamo

to drive the parametric modeling of our building components in Revit. We had the option of either updating our

previous models, or creating new models with new parameters to be altered.

Design Concept

For my design project, I chose to re-use my previous model

(which can be seen in the blog post below).

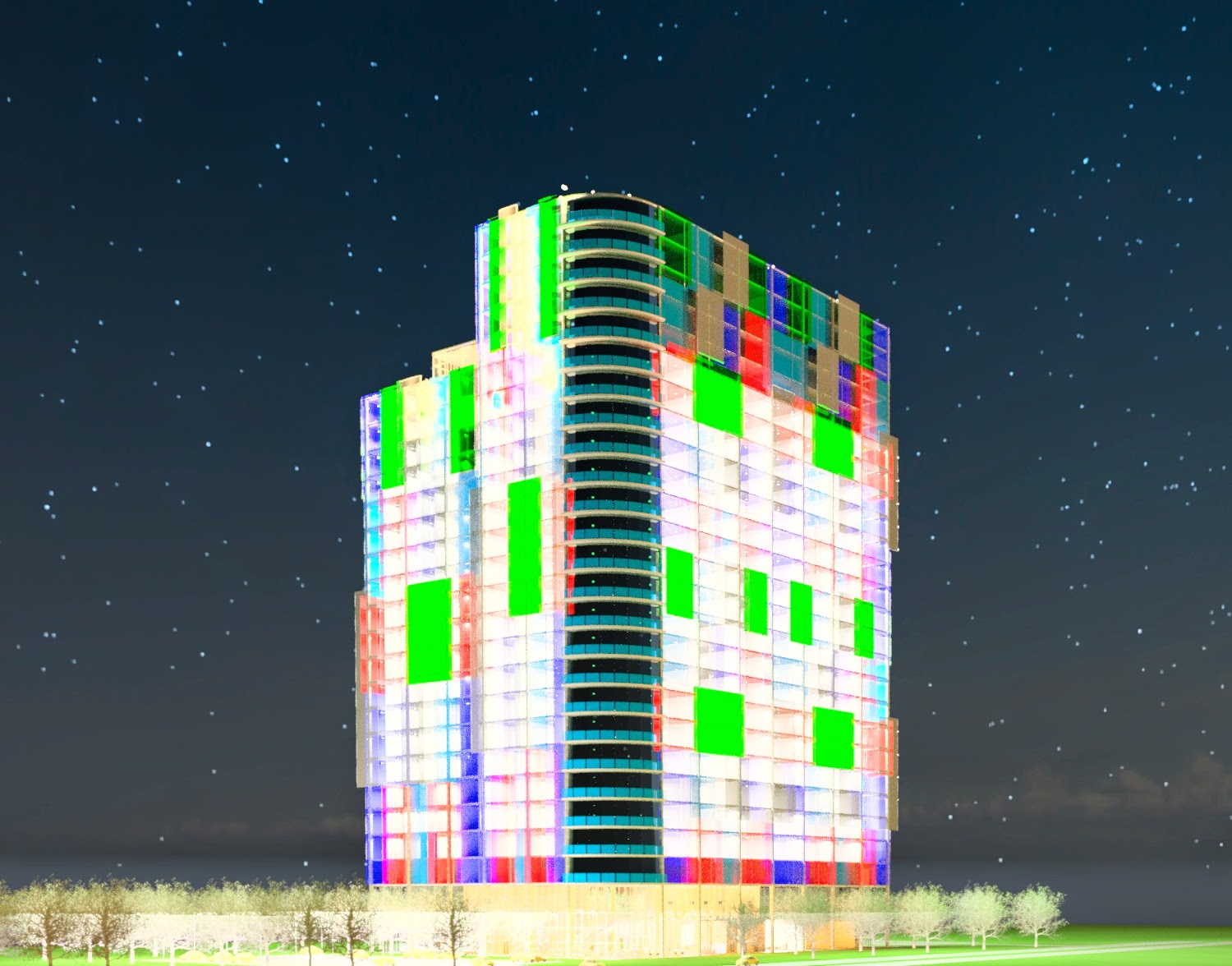

It is a 25 story conceptual high rise living apartment/hotel complex

located in Seattle, Washington. It is an

L-shaped building where the shorter leg side is made up of 20 stories and

contains the hotel side of the apartment and the restaurant on the lower

level. The long leg side is made up of

25 stories and contains the apartment side of the building.

For this project, the building façade was my primary

focus. The concept for the building façade

was to have a series of large, multi-colored glass panels that extruded from

the building surface. Each panel would

be extruded a different depth from the building surface. The color pattern and extrusion depth pattern

are to appear randomized in order to give a unique aesthetic look to the

building.

Preliminary Design

For my preliminary design, I decided to remodel my original

building façade using a different approach.

This time I wanted to use a combination of adaptive point panels and

curtain panel by pattern instead of only adaptive point panels like I did for

my previous design. My thoughts were

that it would make the building façade much smoother, and faster when loaded

into the model as well as easier to control when using Dynamo.

To begin, I started by creating 5 separate square adaptive

point panels and assigning them material property parameters. The materials I gave them green glass, blue

glass, navy glass, light gray glass and dark gray glass (all were

created). Once the individual adaptive

panels had been created, I opened a rectangle curtain panel by pattern, created

a surface and divided that surface into 25 segments (5x5 gridlines). From here, I loaded in each of the 5

different color adaptive panels, and created a random grid system which will be

used as the main façade component.

Next I opened up my mass model and loaded in the curtain

panel by pattern façade that I created and assigned it to be the surface of my

building. On certain faces of the building

I only used one of the façade curtain panels, while on others 2 or 4 were

required in order to keep the sizes of the panels proportionate to one

another.

Finally, I made sure that all of the parameters I wanted to

change (extrusion depth and panel color) were properly nested into the current

mass family.

Once this was completed, the next step was to utilize dynamo

to drive the parameters.

Dynamo Model

When programming the dynamo segment of my project, there

were 2 main parameters that I wanted to be able to change simultaneously and

with ease: The individual glass panel colors, and the extrusion depth of the

individual glass panels. To reach this

final design, there were three major steps I took:

·

The Test Phase

·

The Combination Phase

·

The Randomization Phase

The Test Phase

The test phase was exactly what it sounds like, it was the

phase of my design where I wanted to test my idea on a single panel to ensure

that it worked properly. In order to

begin I made use of a few different dynamo parameter drivers: “Set Element

Parameter”, “Select Model Element”, “Get Material By Name”, and “String”.

To make these 4 parameter drivers work properly, I first had

to select the element in my model I wanted to change. In this case, the element that I wanted to

change was one of the 14 different curtain panels that made up my façade. Once selected, I plugged that box into the “element”

slot of the “Set Element Parameter” box.

Next, I needed to tell Dynamo which parameter of the selected element I

wanted to change. Therefore in one of

the “String” boxes, I typed the name of one of the 5 different material

parameters for the selected element (Navy/Green/Blue/Light Gray/Dark Gray) and

plugged that box into the “param” slot of the “Set Element Parameter” box. Finally, I needed to tell Dynamo what value

to give the parameters. To do this I

made use of another “String” which I gave the name of the material I wanted to

be assigned to the parameter selected. I

then plugged that “String” into the “Get Material By Name” box and then plugged

that box into the “value” slot on the “Set Element Parameter” box.

Once everything was connected, I ran the Dynamo and the

material changed to whatever material I specified it to be, thus indicating

that my test phase was correct.

The Combination Phase

For this phase of the project, instead of recreating the

same process above for each and every panel on each and every façade, I decided

to make use of “Lists”. The “Lists”

allowed me to combine all 5 different panel color parameters as well as all 5

of the materials into one box and then feed that information to the “Set

Element Parameter” boxes. The only

inconvenient thing was that the “Set Element Parameter” box did not accept a “List”

for the “Select Model Element”.

Therefore, I had to create 14 different “Select Model Element” boxes and

14 “Set Element Parameter Boxes” in order to properly drive the entire building

façade at once.

Once all 14 of both box types were created I attached each “Select

Model Element” box to a corresponding “Set Element Parameter” box and selected

each of the 14 curtain panels that made up my façade. Next, I attached 5 “Strings” (each with a

different parameter for the different color panels) to a “List” and plugged

that list into each of the 14 “Set Element Parameter” boxes. Finally I attached the other 5 “Strings”

(each with a different material property) to a corresponding “Get Material By

Name” box (5 boxes), then attached each of those boxes into another “List” and

finally attached that list to each of the 14 “Set Element Parameter” boxes.

When I ran the Dynamo program, everything worked well and I

could change the material properties to whatever I wanted and the corresponding

panels would also change.

The Randomization Phase

For this phase, I wanted to make the color pattern on the façade

of my building randomize each time that the code ran. In order to do this, all that was required

was to make the list that contained the material properties random. Therefore, I made use of a parameter driver

box named “Shift List Indices”. This

parameter driver box shifts the current list based on a given number. For example, if the number were 3, it would

shift all the list values up 3 spaces moving the first, second and third values

to the end of the list. To make it

randomized I made use of the “Random Number” box and multiplied the random

number by 5 (five is the number of parameters) since the random number is only

from 0 to 1. Next I made sure to round

the number up to a whole number after it has been multiplied, and finally this

value will be plugged into the “amt” slot of the “Shift List Indices” box.

Once that was completed I plugged the list into the “Shift

List Indices” box and then plugged that box into the 14 different “Set Element

Parameter” boxes.

When I ran the Dynamo program, the color pattern changed

each and every time. I had achieved a

truly randomized pattern.

Panel Extrusions

Once this design was completed for the panel color pattern,

the next step was to make a randomized panel extrusion pattern. This was done in the exact same manner as the

panel color pattern was done. The only

different was instead of using “Strings” and “Get Material By Name”, I used “Number”

to give an extrusion depth value to the panels.

Also, so that I could change both the material color pattern

and the extrusion depth pattern on the façade at the same time, I made sure to

link the already created “Select Model Elements” to 14 new “Set Element

Parameters” (which control the

extrusion) as well as the original 14 (which control the material color pattern).

Final Results

Here you can see the final results from running the Dynamo

program a few times. Notice how the

color pattern changes as well as the extrusion depth pattern changes each time

that the program runs.

.rvt_2014-Apr-20_02-20-40AM-000_3D_View_2.jpg)

.rvt_2014-Apr-19_10-57-22PM-000_3D_View_1.jpg)

.rvt_2014-Apr-19_10-57-22PM-000_3D_View_7+(1).jpg)